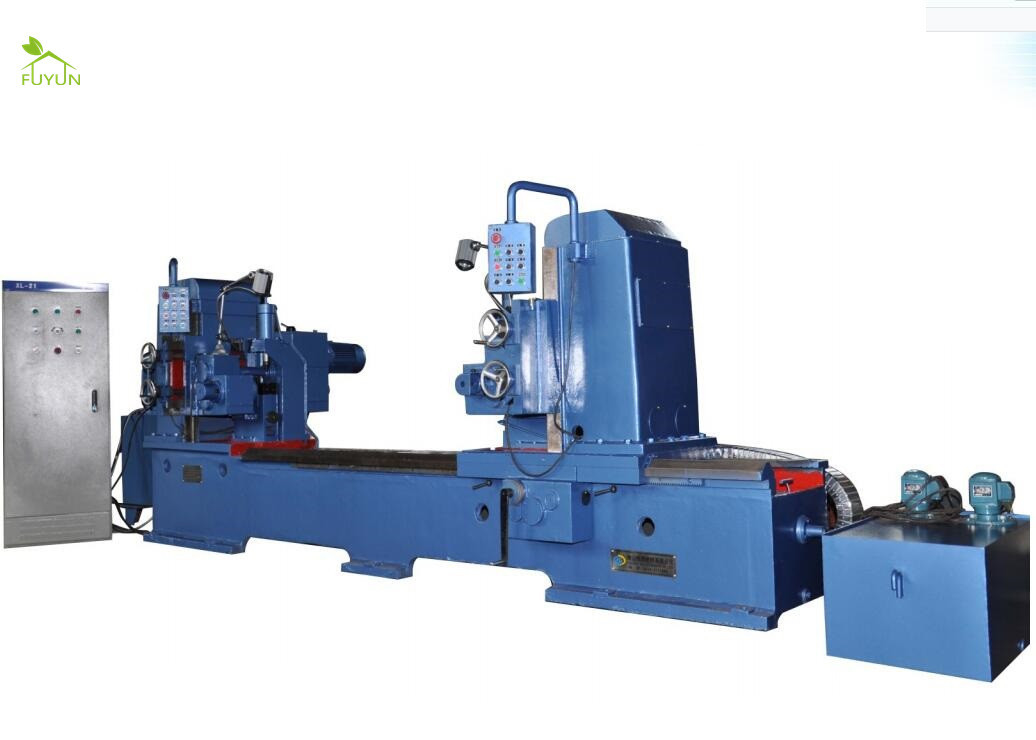

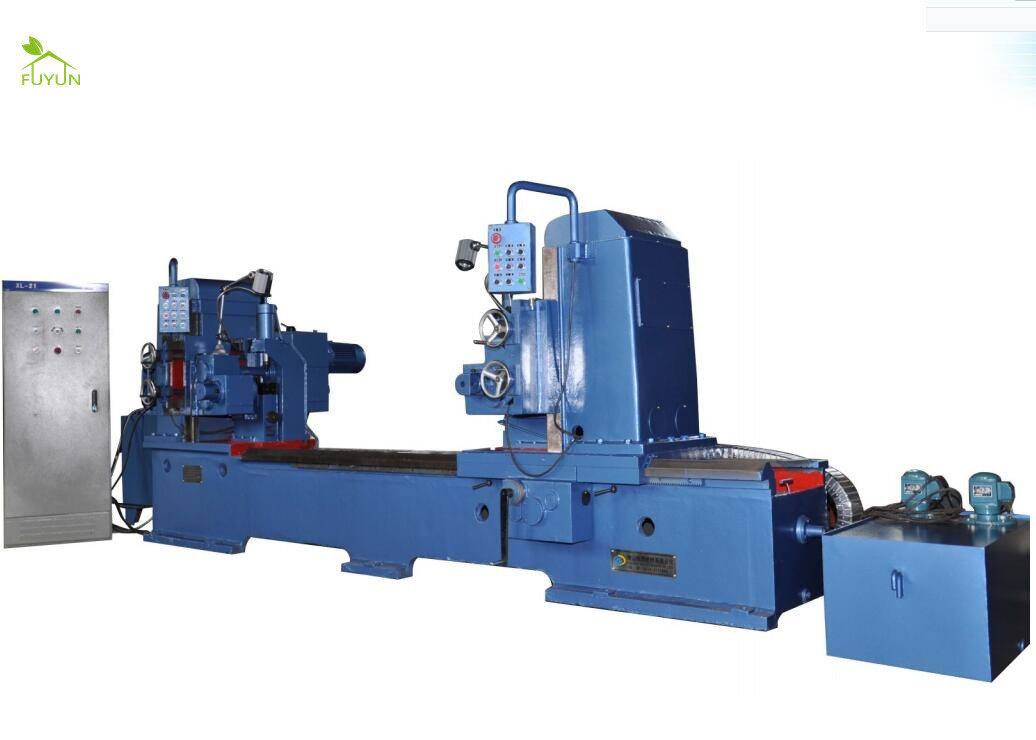

2300mm Mining Roller Conveyor Shaft Both Ends Automatic Milling Machine Dia20mm

Qucik Detail:

machine size: 4050×1300×1600mm

machine weight: 5500kg

Diameter of roller shaft processed: Φ20~Φ60mm

warranty: 5 years

Length of roller shaft processed: 200~2300mm

Product Description:

Tangshan Hengmao Machinery Co.LTD.. located in the eastern part of Tangshan Lubei emerging industrial park,with constantly forging ahead and in perfect,which has developed into a first-class machinery, electronics welding,computer control, and other professional technology and equipment design and manufacturing company.Our company are majored in the production of roller machine:Steel tube chamfer cutting off tool machine Steel tube double-ended automatic hole milling machine,CO2 gas shield double gun automatic welding machine.Roller automatic press mounting machine,Carrier roller shaft slot flat double-end milling machine Chamfer milling machine shaft end play center hole etc.

The Company has sophisticated processing equipment,strong technical force, product quality, its perfor- mance has reached the advanced level in the same industry and has been recoanized by the industry users .The products get through the national IS09001:2008 Quality Management System Certification.

The company has a large number of production technology backbone with extensive practical experience personnel with hiah auality. strong technical advantage .The company carries out strict auality control from product desian. production to assembly of the entire process.which wins many customers with the honest repu- tation and reliable product aualitv.and the products are exported to Russia. Indonesia and other countries

We provide users with the most preferentia pricethe most hiah-auality products. the most excellent service in line with "honest and trustworthy,the user first" business philosophy , to meet the reauirements of users.

This machine is an automatic equipment which could process the two ends of the belt conveyor roller shaft by a single clamping, which could meet the requirements of the processing of roller shaft produced both at domestic or abroad.

Because every roller shaft has four grooves, the machine has four spindle boxes, a milling cutter is drove by a spindle box to process a groove.

Workpieces are clamped pm the V-shaped iron by hydraulic. Droved by hydraulic, the four spindle boxes move up and down when processing, to realize fast forward, work into (cutting) and fast backward. The electronic control system applied imported programmable controller (PLC) as the center for process control, which with high degree of automation, high efficiency and reliability. It’s suitable for volume production of roller shaft.

Technical Parameter:

| specification |

XZ36-6×230 |

XZ36-6×270 |

| Speed for spindle |

500,700,900r/min |

500,700,900r/min |

| Diameter of roller shaft processed |

Φ20~Φ60mm |

Φ20~Φ60mm |

| Length of roller shaft processed |

200~2300mm |

200~2700mm |

| Processing shaft groove width |

6~45mm |

6~45mm |

| Cutting depth |

0~5mm |

0~5mm |

| Spindle motor |

3kW×2(SET) |

3kW×2(SET) |

| Oil pump motor |

5.5kW |

5.5kW |

| Hydraulic system Working pressure |

1.5~4MPa |

1.5~4MPa |

| Hydraulic System Flow |

31L/min |

31L/min |

| cooling bump motor |

125W×2 |

125W×2 |

| equipment size |

4050×1300×1600mm |

4450×1300×1600mm |

Package & Delivery:

Thepackage is import wooden box. If export to european countries,the wooden box will be fumigated. If container is too tigher,we will use pe film for packing or pack it according to customers special request. The machine can be shipped in 25 days, and we cooperate with DHL, TNT, FEDEX and so on, we make sure the machine can arrive on time.

Factory Show:

FAQ:

![]()

![]()

![]()

![]()

![]()