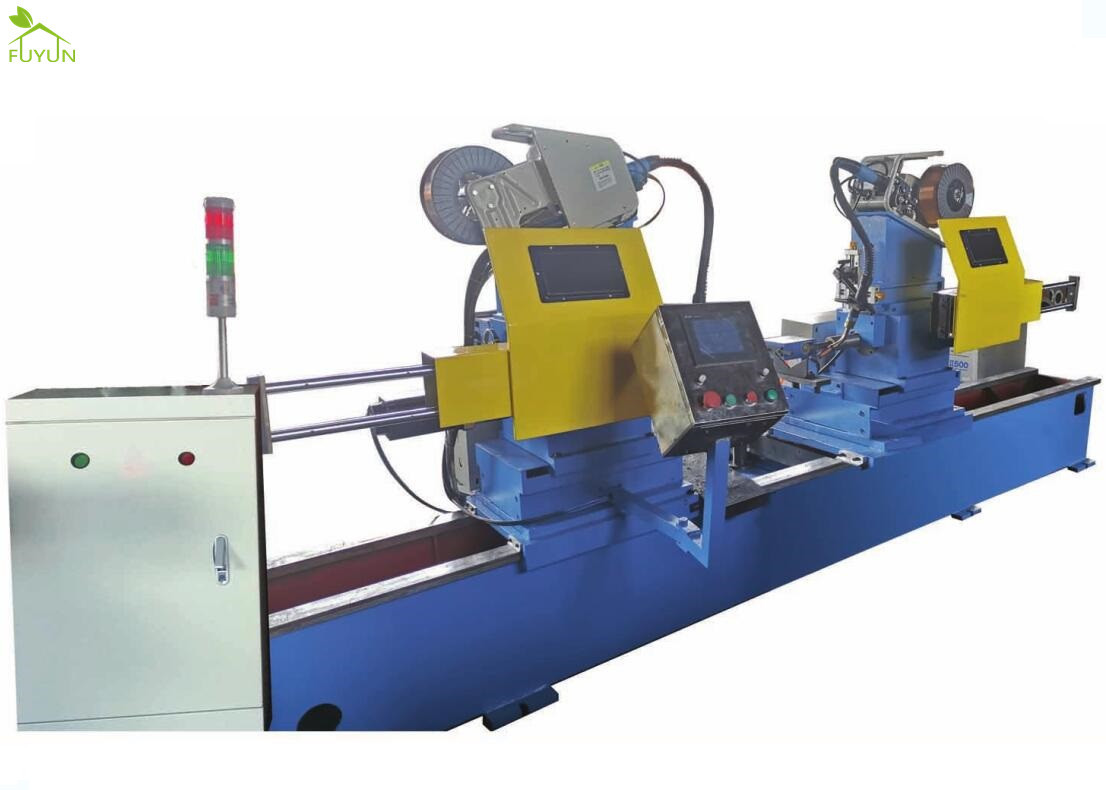

Heavy Duty Belt Conveyor Roller Pipe High Speed Automatic Welding Machine Dia 219mm

Qucik Detail:

machine size: 4600×800×1500 mm

voltage: 380V

current: 350A

warranty: 5 years

machine weight: 5500kg

Length of weldable workpiece: 200~2600 mm

Diameter of weldable workpiece: Φ89~Φ219 mm

Product Description:

Our factory located in the eastern part of Tangshan Lubei emerging industrial park,with constantly forging ahead and in perfect,which has developed into a first-class machinery, electronics welding,computer control, and other professional technology and equipment design and manufacturing company.

Our company are majored in the production of roller machine:Steel tube chamfer cutting off tool machine Steel tube double-ended automatic hole milling machine,CO2 gas shield double gun automatic welding machine.Roller automatic press mounting machine,Carrier roller shaft slot flat double-end milling machine Chamfer milling machine shafenplacenter hole etc.

The Company has sophisticated processing equipment,strong technical force, product quality, its perfor- mance has reached the advanced level in the same industry and has been recoanized by the industry users .The products get through the national IS09001:2008 Quality Management System Certification.

The company has a large number of production technology backbone with extensive practical experience personnel with hiah auality. strong technical advantage .The company carries out strict auality control from product desian. production to assembly of the entire process.which wins many customers with the honest repu- tation and reliable product aualitv.and the products are exported to Russia. Indonesia and other countries

We provide users with the most preferentia pricethe most hiah-auality products. the most excellent service in line with "honest and trustworthy,the user first" business philosophy , to meet the reauirements of users.

This machine is primarily used to conduct the circular seam automatic welding of the roller cylinder and the bearing seat. The machine is equipped with two gas shielded welding machines. Both ends can be welded at the same time in one time, and the welding speed can reach 2000mm/min. Compared with the traditional model (with speed of 800-900mm/min), the welding speed is doubled, making it perfect equipment for mass production. By using programmable controller control, the production efficiency and welding quality are improved.

The main spindle box at the left and right sides are adjusted synchronously with the center as the base point; a stopper is set. The mechanism can be lifted and lowered by combining manual and automatic means. Except material loading and unloading, all other processes are completed automatically, with simple and reliable adjustment; the degree of automation is high.

Technical Parameter:

| Specs |

NZC3-2×350KRHGN |

NZC3-2×500KRHGN |

| Length of weldable workpiece |

200~2600 mm |

200~2600 mm |

| Diameter of weldable workpiece |

Φ89~Φ219 mm |

Φ89~Φ219 mm |

| Input power supply |

Three phase 380V50Hz |

Three phase 380V50Hz |

| Rated load duration rate |

60% |

100% |

| Rated output current |

350 A |

350 A |

| Applicable welding wire |

Φ0.8~Φ1.2 mm |

Φ1.2~Φ1.6 mm |

| Shielding gas flow |

10~25 L/min |

10~25 L/min |

| Speed of spindle |

1~10 rpm |

1~10 rpm |

| Stroke of clamping cylinder |

200 mm |

200 mm |

Adjustable angle left and right of

welding gun |

±20° |

±20° |

Adjustable angle backward of

welding gun

(pass the spindle center) |

0-17° |

0-17° |

| Physical body of machine |

4600×800×1500 mm |

4600×800×1500 mm |

| Operation environment (indoor) |

Temperature: -5℃—40℃;

average relative humidity less than

80% |

Temperature: -5℃—40℃;

average relative humidity less than

80% |

Package & Delivery:

the product is packed in waterproof file and standard carton, we make sure the product good in transportation. we will send machine on time and choose TNT, DHL, FEDEX and so on famous international logistic company. we also packed and deliver as customer's special requirement.

Factory Show:

FAQ:

![]()

![]()

![]()

![]()

![]()

![]()