Package & Delivery:

the product is packed in waterproof file and standard carton, we make sure the product good in transportation. we will send machine on time and choose TNT, DHL, FEDEX and so on famous international logistic company. we also packed and deliver as customer's special requirement.

![]()

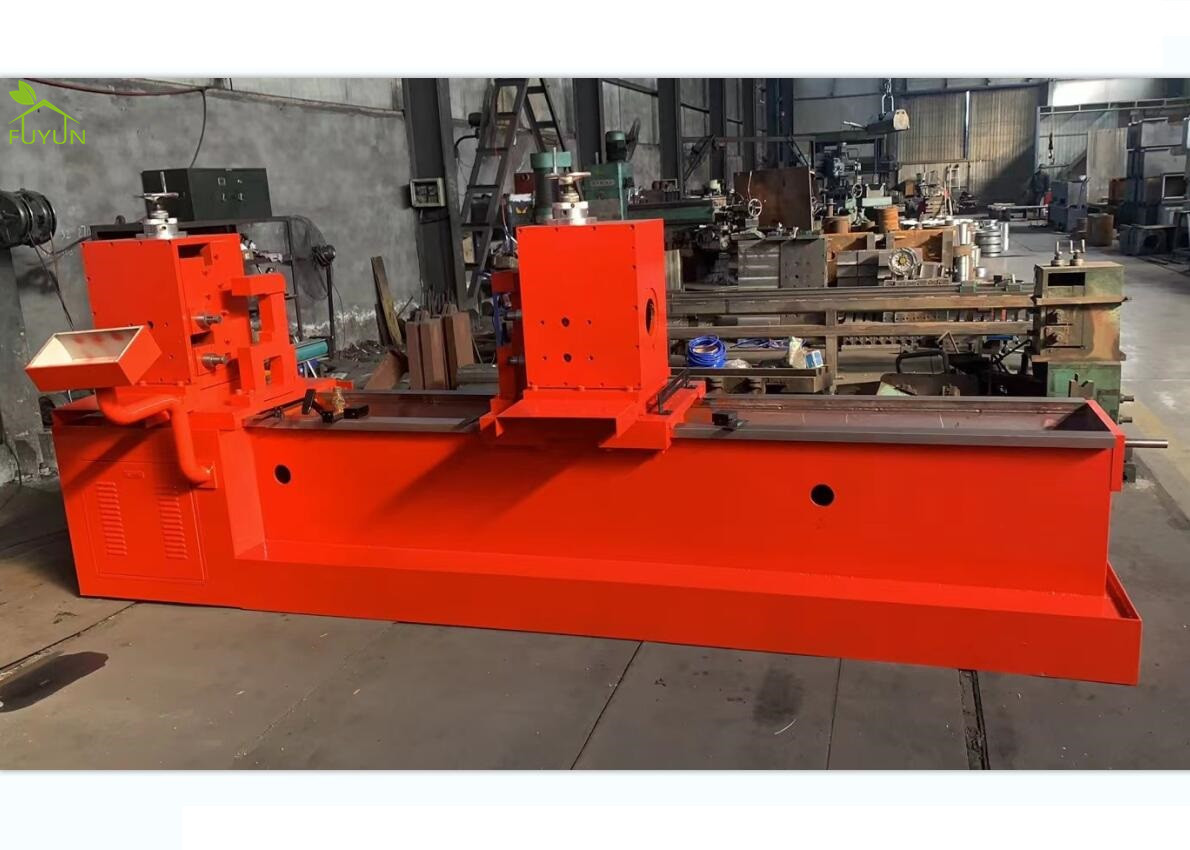

Factory Show:

![]()

![]()

![]()

![]()

FAQ:

![]()